KTI-Project HCPVT – Solar Concentrating Photovoltaic System

Funding source: external pageCTI-The Commission for Technology and Innovationcall_made

Partners: external pageAirlight Energycall_made, external pageIBM Researchcall_made, external pageNTB MNTcall_made

Background – Today solar photovoltaics (PV) remains the fastest growing power generation technology by installed capacity in the world. Yet, the technology has its limitations, most importantly its low efficiency (around 15% for direct solar irradiation) compared to other power generation technologies. A substantial improvement of this efficiency is obtained by the Concentrating Photovoltaics (CPV) technology. Optical concentrators are used to increase the solar radiation density on the PV cell, which leads to a reduction of cell area needed for the same amount of power production. Since concentrators (e.g. parabolic dishes) use cheaper materials and are often easier to manufacture than PV cells, there is a notable potential for overall cost reductions. Furthermore, CPV uses the more expensive triple junction PV cells that reach comparatively high efficiencies, especially at high solar concentrations. Using the same amount of land, CPV systems can produce more electricity, more efficiently and using much less PV material than conventional PV systems.

CPV systems are classified following their concentration intensity:

- low concentration: from 2 to 10 suns (1 sun = 1000 W/m2)

- medium concentration: from 10 to 100 suns

- high concentration: greater than 100 suns

Low concentration systems can use conventional silicon PV cells without cooling or tracking systems. Medium concentration systems require high-efficiency PV cells, cell cooling and sun tracking. High concentration systems require advanced multi-junction PV cells, complex optics and tracking systems, and active cooling and thermal damage prevention.

While High Concentration PhotoVolataic (HCPV) systems achieve high conversion efficiencies, the cost of produced electricity remains comparably high. Main reasons are the high cost of involved materials (PV cells and concentrator) and system complexity due to tracking and cooling.

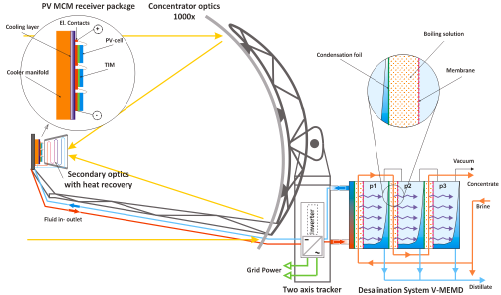

An approach to reduce the electricity generation costs is to utilize the thermal energy harvested during the cooling of the PV cell for purposes such as hot water, drinkable water - by means of thermal desalination equipment exploiting the waste heat - and air conditioning - by means of a thermal driven sorption chiller [Fig. 1] and thus increasing the overall efficiency.

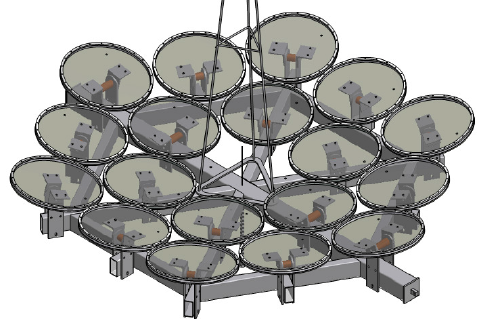

Further cost reductions can be achieved by using innovative materials and concepts for the system optics [Fig. 2].

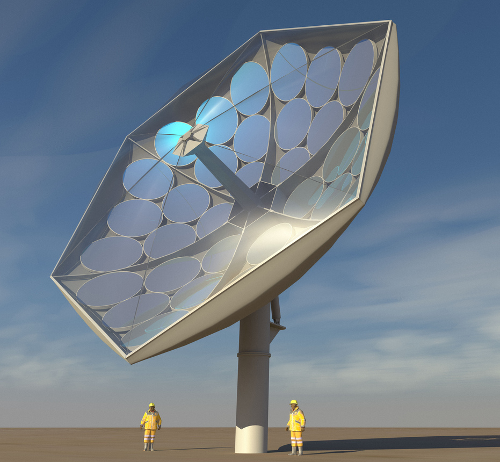

Goal – The goal of the project is to realize a cost-competitive innovative High Concentration PhotoVoltaic Thermal (HCPVT) system able to convert 80% of the collected solar energy into useful electrical and thermal output at a Levelized Cost of Energy (LCOE) between 0.07 and 0.1 $/KWh [Fig. 3]. Novel materials for a low-cost large dish-like concentrator and a high performance receiver are exploited for mass-production. The main commercial goal is a solar technology that increases the conversion efficiency from solar-to-electrical beyond 22%, reduces the cost per aperture area below 250 $/m2, and allows additional recovery of at least 50% thermal energy. Solar radiation is concentrated 2000 times onto a microchannel-cooled receiver holding a dense array of ~40% efficient triple junction PV chips able to extract 50% of the incoming energy as heat while maintaining the solar cells at safe temperatures. An extremely high concentration and a radically low cost product (more than 3 times lower than comparable systems) will be achieved by trackers and primary optics composed of inexpensive pneumatic mirrors and structures made of concrete.

Objectives – The objectives of the project are divided into 3 main parts, corresponding to the areas of expertise of the different project partners:

- Large area concentrator optics (ETH and Airlight Energy)

- High density receiver module (IBM and NTB NMT)

- System integration (IBM, Airlight Energy, ETH)

The objectives of the project are to design, optimize, construct and test the HCPVT system, the role of ETH being focused on the optical design of both primary and secondary concentrators. Specific tasks include:

- Assessment of strategies and design of primary and secondary concentrator

- Assessment and implementation of fabrication techniques

- Implementation of secondary optics

- Characterization of optical system and processes

- Build-up of primary concentrators for prototypes

- Definition of module or sub module concept

- Evaluation of technologies and designs enabling dense array connections

- Establishment of process flow for low-cost integration of 3J PV cell arrays

- Design and implementation of high performance cooler for energy reuse

- Receiver module characterization

- Receiver prototype build-up

- Definition of interfaces for system integration

- Interface management and subsystems

- Build-up of integrated prototypes

- Prototype characterization

Project-related Publications