EU-Project CSP2 – Concentrated Solar Power in Particles

Project website: external pageEuropean Commissioncall_made

Funding source: external pageEuropean Unioncall_made

Partners: external pageProcedes, Materiaux et Energie Solaire (France)call_made, external pageLaboratoire de Genie Chimique (France)call_made, external pageUniversity of Warwick (United Kingdom)call_made, external pageInstituto IMDEA Energia (Spain)call_made, external pageCOMESSA (France)call_made, external pageTorresol Energy (Spain)call_made, European Powder & Process Technology (Belgium)

Background – The use of concentrated solar power (CSP) is an important step to cover rising energy needs while at the same time reducing CO₂ emissions. To produce electricity on a competitive basis the efficiency and safety of CSP plants have to be improved. A limiting factor of existing CSP plants is the heat transfer fluid (HTF).

The aim of the CSP2 Project is to use a dense gas-particle suspension as an alternative HTF that allows working temperatures higher than 550°C. The solid phase consists of any particulate mineral, like quartz sand, that withstands high temperatures. The solid particles can also be used as a thermal energy storage medium due to their high heat capacity.

Compared to standard HTFs, the particulate solid material is widely available, inert, and has high heat resistance. It has advantages regarding environmental impact, safety concerns, and CSP plant efficiency. Large quantities of the particles can be produced at low cost without any chemical process development.

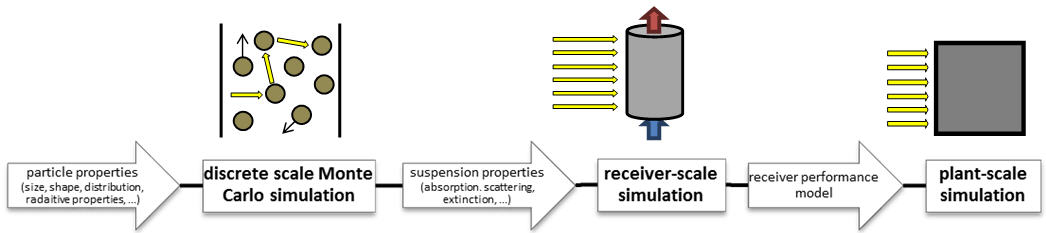

Objective – Overall goals for the project are to develop dense particle suspension receiver technology and to demonstrate the performance of a pilot-scale receiver with 100-150 kWth capacity. ETH Zurich's role in the CSP2 project is primarily concerned with modelling the behaviour of the particle suspension in the receiver. As illustrated in Fig. 1, simulations will be performed first at the particle scale to determine properties of the suspension. The results will be used to develop a model of the receiver performance, which will be incorporated into an overall model of a CSP plant.

Modeling objectives:

- Heat transfer and fluid flow modelling of the particle-gas suspension.

- Influence of particle properties and receiver dimensions on the power plant efficiency.

- Validation of the numerical model with experimental results from a pilot plant.

Project-related Publications