KTI Project High-Temperature Combined Sensible/Latent Heat Storage

external pageWebsite at CTIcall_made

Funding source: CTI through external pageSCCER Heat and Electricity Storagecall_made

Partners: external pageAirlight Energycall_made, external pageALACAES SAcall_made, external pageSUPSIcall_made

Doctoral Student: Philipp Roos

Project Head: Dr. Andreas Haselbacher

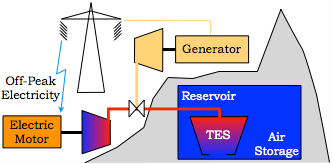

Background – Pumped hydro storage (PHS) is heavily used in Switzerland to generate electricity. It will play an even more important role in the future due to the fluctuating nature of renewable energy sources such as solar and wind power. Therefore, the total capacity of PHS is scheduled to be expanded significantly as part of the Energy Strategy 2050. However, the construction of additional PHS plants is very costly and opposed by environmental groups. This motivates the investigation of advanced adiabatic compressed air energy storage (AA-CAES) as a complement to existing and alternative to new PHS plants. Existing studies indicate that AA-CAES can offer similar capacity, approach the efficiency, and exhibit lower costs than PHS. AA-CAES plants achieve high efficiencies because the heat generated during compression is stored and then reused during expansion, see the Figure below. A unique feature of AA-CAES is that its basic operating principle has been proven in practice by the diabatic (i.e., without thermal storage) plants in Huntorf, Germany (321 MW) and McIntosh, USA that have been operating since 1978 and 1991, respectively.

Objective – Two basic thermal storage concepts will be investigated. The first concept is based on sensible heat storage using a packed bed of rocks. Since this suffers from a drop of the outflow temperature during the discharge cycle with an attendant negative impact on the overall cycle efficiency, we will also investigate a second concept in which a limited amount of encapsulated phase-change materials is added to the packed bed. Initial investigations have confirmed the promise of this novel approach. The research will look at the selection of appropriate phase-change and encapsulation materials as well as their cycling stability. The two concepts will be evaluated in terms of the efficiency and the material costs relative to storage capacity. The close collaboration with industrial partners Airlight Energy Ltd. and ALACAES SA will provide access to a large-scale storage being built at their facility and result in technological advances that have direct industrial relevance and that are geared toward an eventual market implementation.

Project-related Publications